East Lake’s New Bunkers Include a Solution for Washouts

East Lake Golf Club has been a treasure of American golf for 120 years. As the host site for the Tour Championship, the eyes of the world are on the course every year. Yet, the infrastructure of the course left a lot to be desired.

Director of Agronomy Charlie Aubry arrived in 2015 and quickly learned from the legendary Ralph Kepple and his team what it takes to ready the course for a Tour event. It was clear the amount of time of effort involved in preparing the bunkers and keeping them playable through late-summer Atlanta storms was immense.

“In 2015 when Spieth won, we had a bunch of rain Thursday through Sunday,” says Aubry. “It was kind of a nightmare trying to keep the bunkers in shape during the championship. They were washing out constantly.”

They experienced the same problem -- only worse -- for the East Lake Cup college event that fall. “The bunkers were essentially destroyed,” he says. “But the crew blitzed it and we were miraculously able to get things ready somehow. That kind of got the conversation started on redoing those bunkers.”

At the time, most of bunkers were 7-8 years old and already contaminated. Many were flashed faces that washed out completely in a heavy rain. “We added some bunkers on 12 and 18 and Ralph decided to test out the Bunker Solution design then. We were really happy with the way they performed during rain events. They drained really well and we didn’t have any issues.”

When the crew rebuilt the short-game area it became a test plot for the Bunker Solution technology for the next five years. “It worked. We became really confident that would be our choice.”

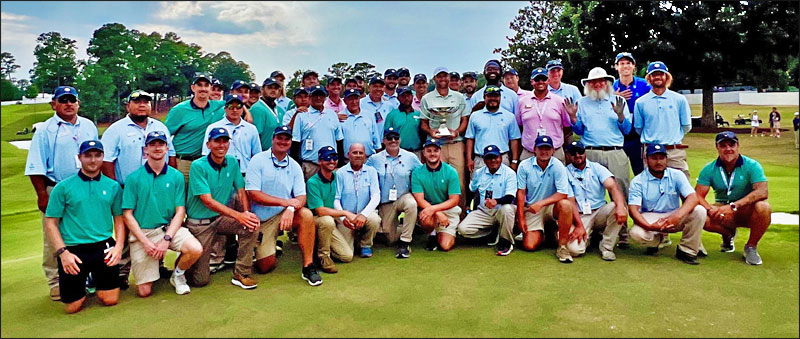

Everything accelerated in 2021 when the club decided to explore options for full renovation and Andrew Green was selected for the project. “We started Sept 6, 2023. It is now August 19, 2024, and the course has been completely rebuilt and we’re ready to host the Tour Championship. Andrew and our construction company, Total Turf Services, did a great job on this project.”

Aubry describes the old bunkers as “the worst of both worlds” both in terms of age and the way the water would flow through them. It was time to change. “Andrew’s design is more grass based. It’s mostly flat-bottom and not as flashed-up as the old style. We were confident in the Bunker Solution design because we’d worked with it for 8 years.”

That confidence is already paying off in terms of labor savings and playability. “The big thing for us is how well these drain and how we can we minimize bunker-related labor, day in and out.”

He’s already seen a big change, particularly during heavy rain events. “We have a crew of 36 and we were averaging 10 times a year that the whole crew would be dedicated to bunker repair. Not anymore. That’s a lot of labor that’s now being applied to other areas of the golf course year-round.”

Aubry says he also won’t miss scrambling to cope with big storms that always seems to pop up during advance week. “We had to redirect everyone to fixing bunkers instead of prepping for the championship. That was a huge problem that we just eliminated with Bunker Solution.”

How do you describe Bunker Solution to other supers?

“It’s not like a foamy liner. The nice part about it is that the liner is kind of an Astroturf material with a grain you can orient any way you want. You try to face the liner in the direction of play. Even if a player gets low and the club contacts the material, they can still get out of it.”